The rate of robotization of industrial manufacturing is going on leaps and bounds not only in Europe, Asia, the United States, but all throughout the world. Let’s see the numbers and facts.

The universal language of numbers

Numbers are an extremely powerful gage that deals with concrete data. With the numbers, we can make calculation and analyze everything in terms of quantity. The significant decisions, as for the investment for example, are made solely based on calculations, as the figure indicates numerical value of profit. Numbers often influence our opinion, shape our deeds and thoughts, and stir our feelings. In the ever-changing world of industries, robotics is gaining more and more niches. And let’s see the numbers why.

Robotization of industrial enterprises in numbers and facts

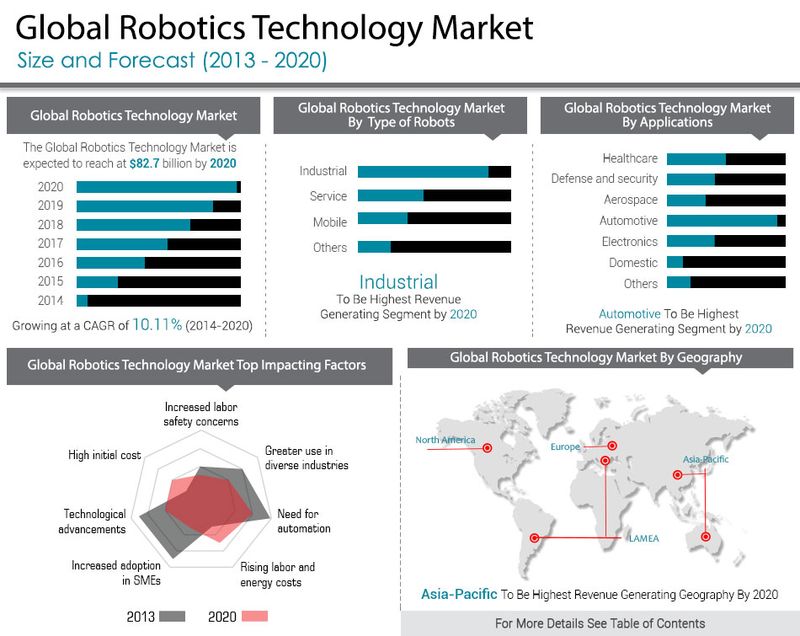

In 2014, the number of industrial robots installed worldwide was more than 200,000. This number is 15% higher than the number of installed robots in 2013. The figures tell us that industrial robots are becoming more and more advanced and together with the innovative technologies come forward on the scene, because they enable the business to compete and win in the market. As long as the researchers keep finding out new areas to apply robots in, the demand for robotics will continue to grow. In 2013, Japan, China, Korea, Germany, and the United States robotics sales made 70% of the total robotics sales. These countries are well entrenched in the robotics market, though the new countries, especially in Eastern Europe, are beginning to invest heavily in the robotization of manufacturing. And as for the year 2016, the index of industrial robotization grew higher.

For example, in Mexico, the demand for robots increased by 30% and reached a new, record level in 2013. The year before the last, in Canada, the robotization rate increased by 29%. It is worth while noting that Canada has been showing a consistent improvement in this field since 2010.

Robotics sales are soaring throughout the industries. Why?

Perhaps, no criterion is as relevant as profit and costs, that is to say, economic benefits. How can robotics reduce expenses and lower production costs? Let’s see. Robotics significantly increases productivity of labor. If you need, robots are capable to work 24/7, they do not require breaks, and thus reduce time of production cycle. Robotization of industrial enterprises increases capacity of workshops, makes work better organized that significantly increases the efficiency of production.

For the owners, the combination of these factors vitalizes manufacturing, reducing its cost and increasing profit. For example, if you invest in the most famous industrial robots by Kuka, Kawasaki, or Fanuc they are capable to pay off in no time. If robotization of industrial enterprises were not effective, the market would have rejected it long ago. A little later, in the new posts, we will show the effectiveness of such modernization on the example of separate workshops, factories and plants.

Conclusion

When you make decisions it is worthwhile taking to account that already today robots play an important role in manufacturing. They constantly increase their influence in all industries, raising efficiency and velocity of production.