As you can see on the graph, the demand for industrial robots is not only growing but has also started to accelerate, despite the global financial crisis to have slowed the world’s economy growth. Therefore, one can’t just say “it’s all because the markets naturally grow”. According to IFR, if this growth preserves, in 2018, 400 thousand robots will be sold against 229 in 2014 and from 2015 to 2018, 1.3 million new units will be installed throughout the world. It means an explosive growth!

Sadly, but at this time, the “raw materials appendages” including the post-Soviet countries will stagnate or even remain in a recession, in the end of the raw materials super-cycle, and there simply won’t be enough money for modernizing and robotization of their economies. If nothing improves the situation, the productivity gap will increase, making them even less competitive, driving directly into the raw materials alcove.

At the same time, in 2015, China, understanding the ruling trends, adopted the national strategy “Made in China 2025”, to modernize and robotize their industries, and to divert from the laborious to “smart production” and “Industry 4.0”. They were inspired by the German concept “Industry 4.0” that was created and declared a little earlier.

Robotization will make it harder for the poor countries even to follow China’s example of industrializing when they play the role of the world’s assembly shops with cheap man-labour. According to the World Economic Forum 2016 report, by the year 2020, development of AI, robotics and related fields, will purge more than 5 million employees. However, according to the World Bank information based on the Oxford Martin School research the share of jobs that can be automated in developing countries makes from 55% for Uzbekistan to 85% for Ethiopia.

China has already climbed into the top 5 robotic sales markets. Japan, the USA, South Korea and Germany constitute 70% of the robotic sales market. What is the pace of robotization in China? In 2014, 57 thousand robots were sold, that is 56% more than the year before. And this is just a quarter of the world robotics market. From 2010 to 2014, its market was growing in average by 40% per year. Although, as for the density of robots to the number of employees in the processing industry it is lagging behind even the world’s average rate. But just think about how enormous this growth rate is.

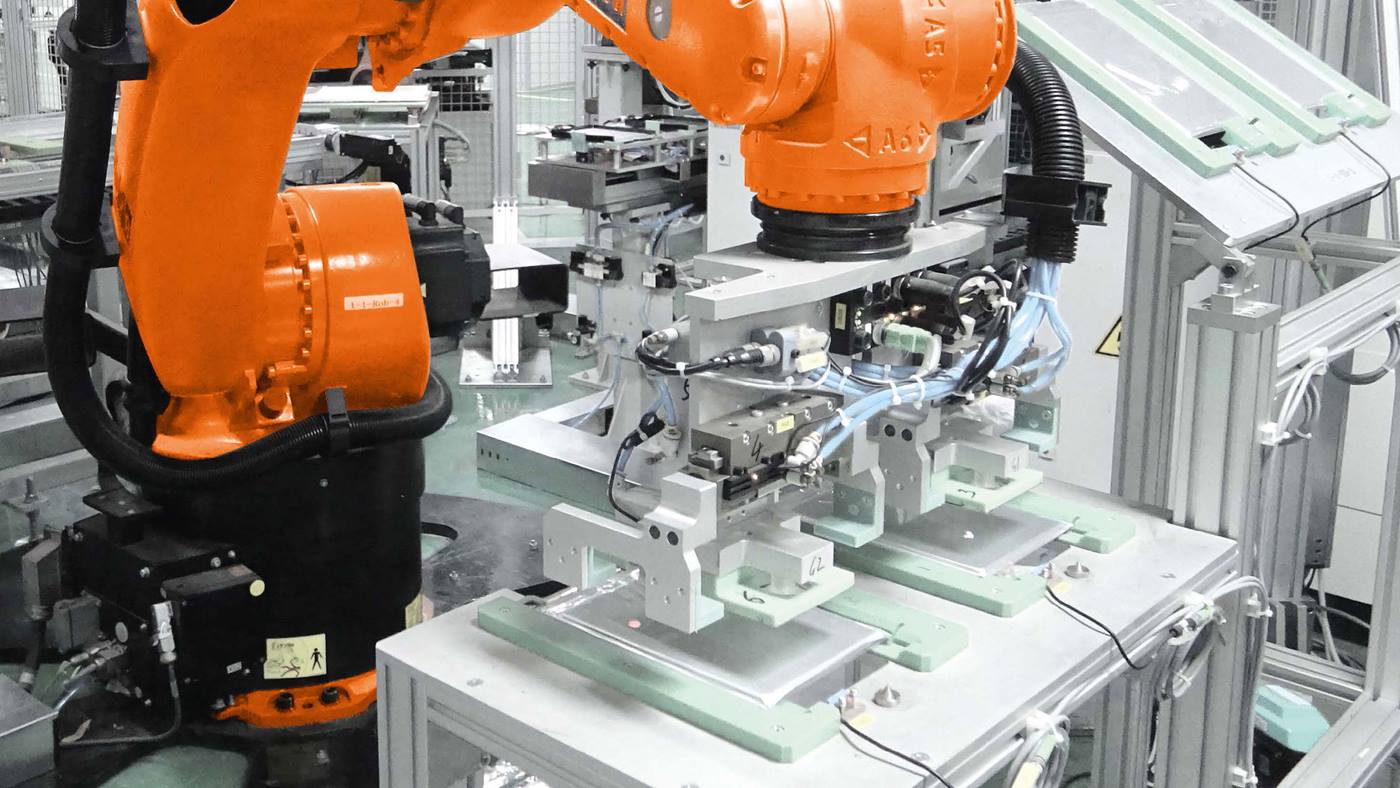

Since 2010, the world’s largest consumer of robots has been the automotive industry. In 2014, the number of integrated robots was 43% higher than in 2013. Although, robotics also conquers new niches. or example, Boeing within the framework of their new technology strategy develops automated fuselage assembly FAUB (Fuselage Automated Upright Build) for their new 777 model substituting the human labour with the robots by the German company KUKA.