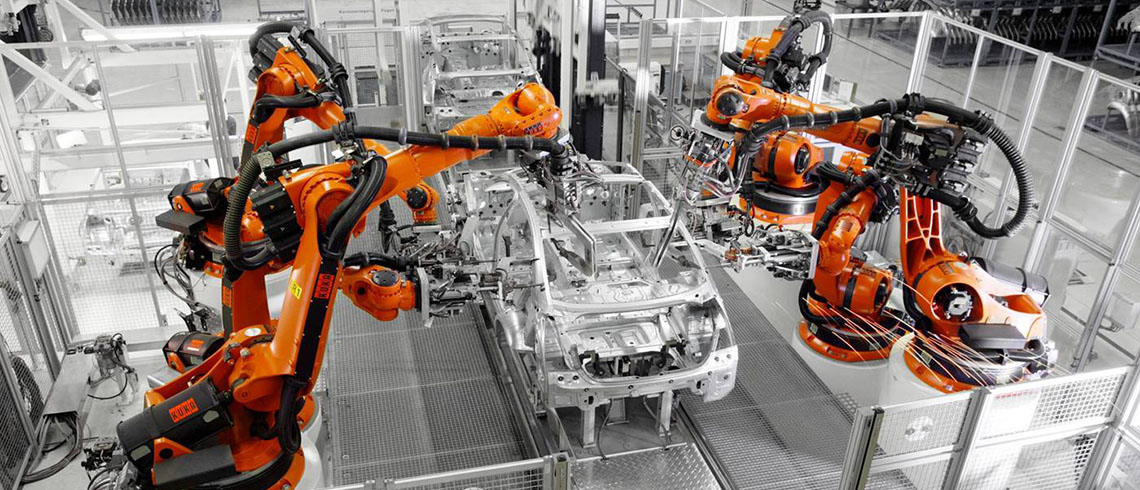

In the automobile manufacturing industry, all major companies are riveted to renovating their manufacturing automation to conquer the highest profit. The KUKA’s company engineering and testing expertise has made it the worldwide leading manufacturer and supplier of the best equipment for the automotive industry.

The automotive industry market dynamics spikes the manufacturers and lures them to advance their technologies in response.

Simple integration and controls allow manufacturers to satisfy constantly growing demands for different automobile models.

KUKA provides individually configured, modular automation solutions for manufacturing and logistics, and contributes to reducing enterprises’ costs.

Check-list: My production line needs automation

What your automobile business will get with the Kuka robots:

- They deliver the highest achievable precision to any operation. This provides the highest product quality and reduces the risk of rejects;

- Manufacturer can use them 365 days a year, three shifts at a time;

- They spare industrial premises;

- They have quick payback;

- They diminish the “human factor” at repetitive works, that require perpetual accuracy and labour safety accommodations.

The Kuka robots are the best in automobile industry

Two KUKA robots weld the dashboard holder for the Mercedes Sprinter.

The six-axis robot Kuka KR 210 L150 F 2000 series became the main component of the solution for automatic transportation of products at the Audi AG plant in Ingolstadt.

Georg Fisher has launched a new foundry, focused on the production of axle components and engines for trucks and cars. KUKA robots guarantee maximum production flexibility and rational use of molds for filling with hot molten iron.

What you get:

Ready and operating production solution

Fully automated production site

Qualitative process at low cost

You understand what processes can be performed more efficiently

Increase in efficiency by an average of 50%

Decent and comprehensive service