As you can see on the graph, the demand for industrial robots is not only growing but has also started to accelerate, despite the global financial crisis to have slowed the world’s economy growth. Therefore, one can’t just say “it’s all because the markets naturally grow”. According to IFR, if this growth preserves, in 2018, 400 thousand robots will be sold against 229 in 2014 and from 2015 to 2018, 1.3 million new units will be installed throughout the world. It means an explosive growth![ … ]

Author: Elen

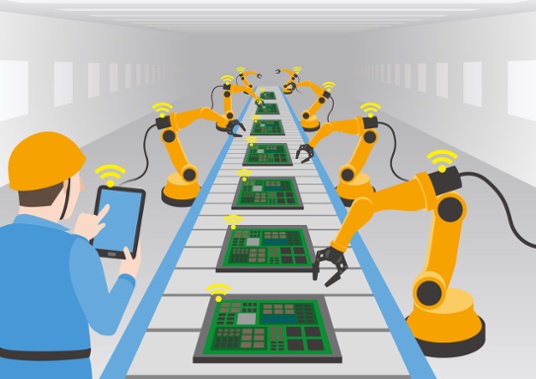

Unprecedented robotics growth recently hit manufacturing

The rate of robotization of industrial manufacturing is going on leaps and bounds not only in Europe, Asia, the United States, but all throughout the world. Let’s see the numbers and facts.[ … ]

Robots and cobots: 5 disparities that you had no clue about

The concept of cobots (collective robots) loomed in 1995 within the framework of a research project piloted by the General Motors Foundation.

[ … ]

Robotic welding: TOP-5 robots-welders by KUKA

Today, the shouting out gap between manual and robotic welding sways metalworking enterprises, and they successfully introduce modern technologies into manufacturing. The most obvious benefits are the better quality of the seam and much higher speed. The method of robotic welding is mainly predetermined by the types of the parts.

[ … ]

Mercedes-Benz entrusts KUKA to innovate manufacturing

Mercedes-Benz harbours hopes by the year 2020 to become the leading automobile producer with the most up-to-date digital technologies. The company’s management board widely introduces modern technologies to maintain high product quality, grow production volumes, while making the life of their employees easier.

Robotic production: 8 benefits that will make you consider it

The enterprises struggle for leadership imposes strict competition on the world and in-state markets. Hundreds of thousands of factories, small and gigantic, are facing the need to automate production. Rather high level of product rejects, hard and noxious working conditions, high wages to employees – does it all sound familiar to you too? Automation of work processes is the right decision to make for a company’s development and prosperity!

1. You will cut down operating costs.

KUKA robots will reduce the main and overhead costs, giving you a hand to compete.

2. You will comply with the high quality standards in mass production and set new ones yourself.

The robots’ high precision ensures consistently high quality of every and each product. With the robots, you will not have the rejects caused by “human factor”: fatigue, inattention, heavy physical work.

3. You will make your employees relish in their new work envitonment.

KUKA in dusty, hot and dangerous working environment is like fish in water. It’s like Albert and Victoria. The only task of human-employees is to learn how to program and control the work the robots do.

4. You will amplify your output.

The main advantage of robots is high productivity. There is no need to stop production at night or for weekends. Thus, the volume of products will rise, the technology and deadlines will be observed, the number of customers will enlarge, so will the profit.

5. Product manufacturing will be much more flexible to manage.

The KUKA robots are so easy to reconfigure that they can switch to numerous tasks and change the products looks at the least expense, and in no time.

6. You will decrease product rejects.

When you resort to automation of manufacturing, you are sure to significantly improve product quality. You can forget about losses and rejects caused by poorly done work or violation of technology.

7. You will reduce staff turnover and additional training expenses.

The process of manufacturing requires qualified personnel and time for training. As for robots, they are much better here: once you programmed them, they are immediately ready to commence.

8. You will reduce capital expenditure.

Robots will reduce your capital costs, as you can easily forecast when the goods are completed and ready for transportation to the buyer.

Does robotization equal automation? Behind the scene.

If you are a business person, you must have already asked yourself “Why do I invest in automation?” “If I robotize a couple of manufacturing areas, when will it pay off?” “What’s the difference between robotization and automation?” But the first your question might be, whether automation or robotics are suitable for your business at all. Briefly speaking, it depends on what your business needs right now.

But if you take it a little bit more serious, we have to answer 3 questions:

– Do your employees often do repetitive work?

– Do your employees’ “just doing their jobs” lower the planned productivity?

– Do you have physical or virtual tasks?

If you answered at least one “Yes” then this area can apply for automation. Depending on the process (virtual or physical), you can automate software, or automate/robotize manufacturing.

Let’s take a closer look at each option.

What does automation mean?

In the era of Industry 4.0, in many industries, automation is very acute. Now, there are two main types of automation: software automation and industrial automation.

Automation of software is the process when programs perform the tasks that usually perform people who work with software.

Business Process Automation (BPA) is a multi-level business process optimization strategy that includes the formalization of all processes in the business and their integration into automation software. The introduction of this type of automation may require a radical restructuring of the business.

Robotic processes automation (RPA) refers to “software robots” that are programmed to use the software to perform the tasks. This technology is easier to integrate into existing business processes.

What does robotization mean?

Robots are programmable machines that can perform a series of operations autonomously or semi-automatically. They are guided in the space by sensors and cameras. Robots can be programmed to perform a tray of tasks, thus easily be applied in different areas of production. The market of industrial robots can offer many solutions from different manufacturers easing it for a business person to make the right choice. Of course, the best would be to contact the representative-companies who already have the data of the area that you need.

What is behind automation of manufacturing?

When we refer to the concepts of “automation” and “robotics”, we usually talk about automation of industrial manufacturing that deals with physical processes. They include robots and control systems that automate performing of industrial tasks.

Taking to account all the above said, what would be the answer to the question: can robots perform processes in manufacturing? If you answer “yes”, please consider robotization option for your business.

Cobots strive for prospects with people

Kuka is planning to expand their markets and go for manufacturing robotics and automation solutions for consumer market.

Till Reuters, CEO of KUKA, announced this direction to have been chosen by Midea, the Chinese home appliances manufacturer, the new owners the Kuka company.[ … ]

KUKA and Volkswagen united for ampler servicing of autos

Do robots impress you? Are you exited with the electric or autonomous cars? And what would you say if someone combined these three?

Guess what, Volkswagen is already doing it! Volkswagen announced expansion of their partnership with Kuka, a world’s leading automation supplier, to research the prospects of the servicing robotics in the market of autonomous and electric cars.

[ … ]

Sleek KUKA wins award at Red Dot Award 2017. Congratulations!

The industrial robot KUKA KR CYBERTECH was rewarded at the Red Dot Award: Product design 2017. CYBERTECH being so sleek and compact makes it work very nimbly and precisely, even at the highest speed.

[ … ]