Mercedes-Benz harbours hopes by the year 2020 to become the leading automobile producer with the most up-to-date digital technologies. The company’s management board widely introduces modern technologies to maintain high product quality, grow production volumes, while making the life of their employees easier.

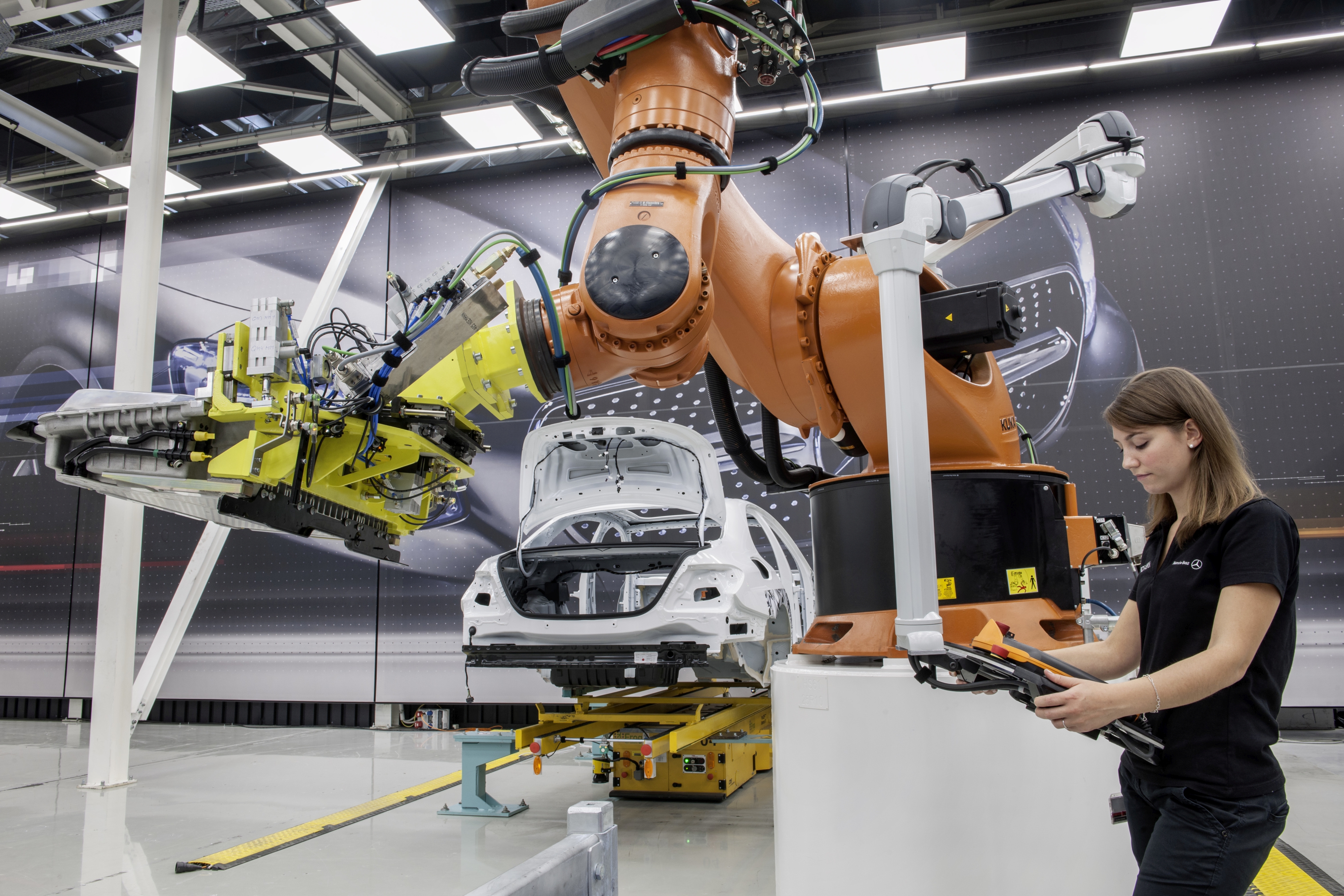

They have equipped their plant with robots and cobots of different sizes, as the size determines functionality for the most part. For example, the KUKA robot is installing an electronic battery into a car, while the operator visually monitors the robot and removes eventual minor obstacles in its trajectory.

They have equipped their plant with robots and cobots of different sizes, as the size determines functionality for the most part. For example, the KUKA robot is installing an electronic battery into a car, while the operator visually monitors the robot and removes eventual minor obstacles in its trajectory.

“Finally, the successful collaboration of humans with cobots has been acknowledged. Cobots would react quickly to touching a human to avoid any injury. And they would also stop motion as the operator’s hand is not longer on their controls.”

Aside from these robots, Mercedes-Benz also integrated mobile platforms to deliver heavy parts to the robot-picker. To introduce mobile platforms, the plant installed more than 6,000 magnets that form an invisible navigation matrix, the rout of the platforms being programmed via a wireless local intranet.

The Mercedes-Benz company has been working with innovative technologies for a long time. When people, machines and industrial processes are intellectually integrated into the “smart factory” network, custom-made high-quality products can be produced in a much faster pace.

Tired of looking for interesting information about robots on the Internet? We will do it for you!